The Smartest Way To Master Your Supply Chain

Get ahead of the competition by closing the supply chain performance gap with the AIO Supply Chain Command Center

Learn more

*Gartner®, Cool Vendors™ in Supply Chain Management Technology, October 21, 2022. GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, COOL VENDORS is a registered trademark of Gartner, Inc. and/or its affiliates and are used herein with permission. All rights reserved. Gartner does not endorse any vendor, product or service depicted in its research publications and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner’s Research & Advisory organization and should not be construed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.The GARTNER COOL VENDOR badge is a trademark and service mark of Gartner, Inc., and/or its affiliates, and is used herein with permission. All rights reserved.

Our Clients

.svg)

.svg)

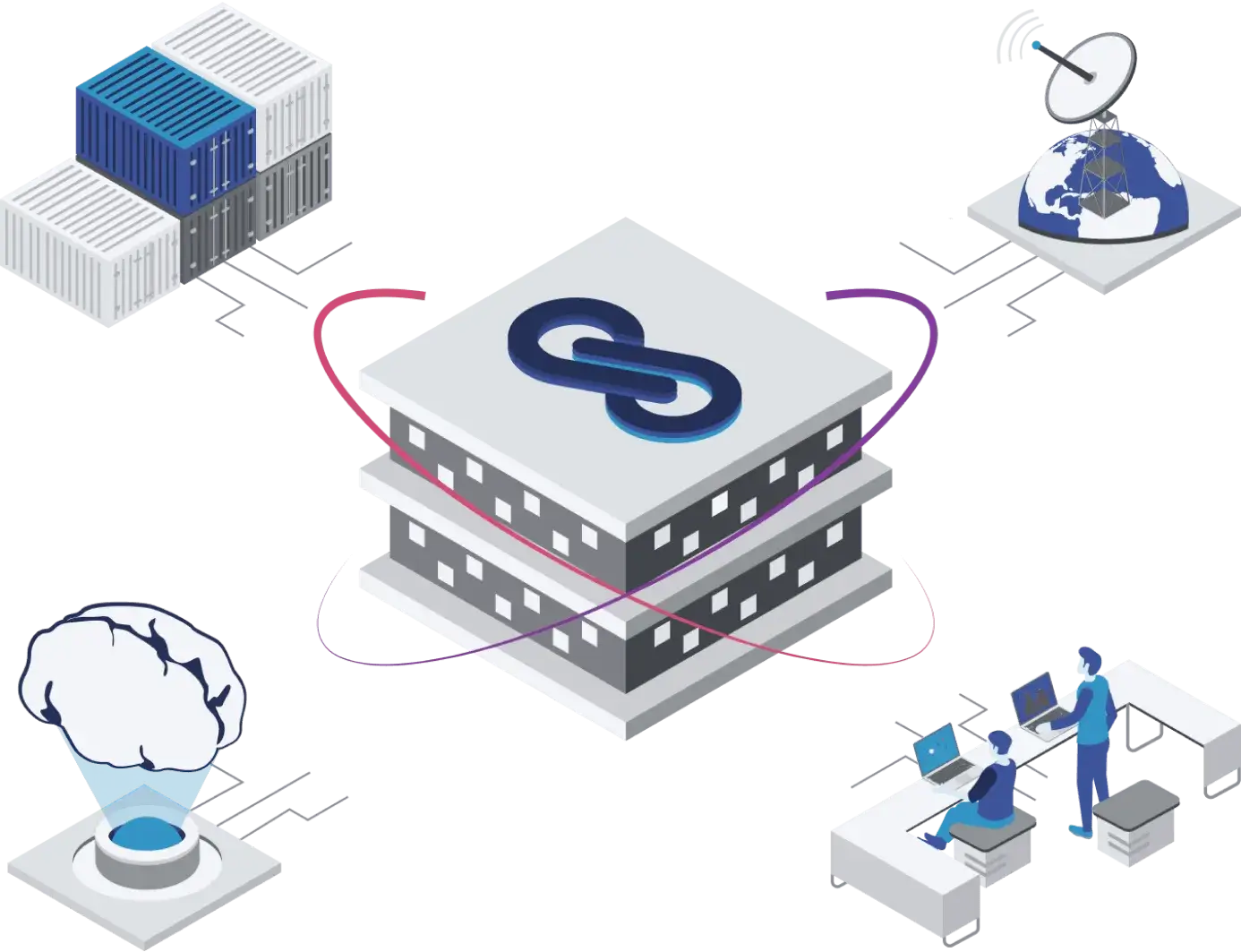

A Closer Look at the AIO Supply Chain Command Center

The AIO Supply Chain Command Center (AIO SCCC) creates a digital supply chain twin through which the end-to-end supply chain is captured and visualized in real time.

Machine-learning and automated, intelligent algorithms continuously analyze events, enable decision-making and recommend measures.

Flexible workflows guide the user through the necessary activities to improve supply chain performance, solve problems in a cross-functional manner and to automate tasks.

This closes the loop from generating insights, making intelligent decisions and achieving impact through result-oriented supply chain improvement execution.

Machine-learning and automated, intelligent algorithms continuously analyze events, enable decision-making and recommend measures.

Real Business Impact Enabled by the AIO SCCC

In an ever-evolving business landscape, high supply chain performance is vital. The rise in supply chain complexities call for a paradigm shift from conventional to future-proof closed-loop approach. Our AIO SCCC and expert-led services give you a competitive edge and improve your top, bottom and green line.

Top 5 Use Cases That Our Clients Are Starting With

Gain end-to-end transparency across your supply chain and break down organizational silos to identify issue root causes through obtaining different functional vantage points.

Find out more

Maintain inventories at the right level to buffer the supply chain against peak demand and low supply – ensuring overall low inventory and high product availability.

Find out more

Integrate sales and marketing planning on volume and value with operational planning to optimally balance cash, cost and service.

Find out more

Ensure high product availability, supply chain flexibility and reliable deliveries to customers by breaking down bill of material structures and connecting data from suppliers to customers in real time.

Find out more

Determine your corporate carbon footprint and decarbonize your supply chain to save the planet and ascertain compliance with latest regulations.

Find out moreWhat Our Customers Say About Us

Satisfaction Score